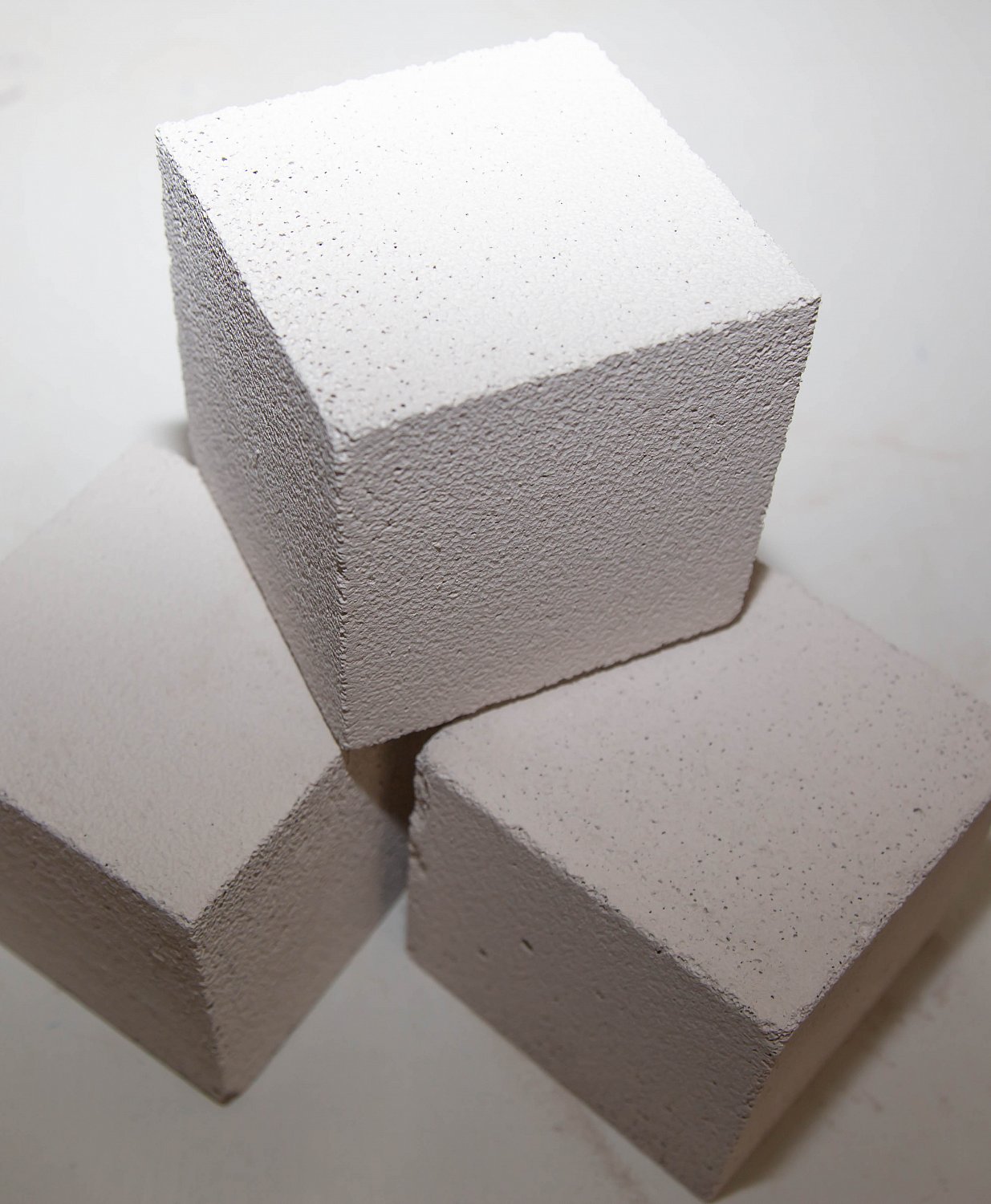

Belarusian cement company has created a unique building material

A completely new, super-strong type of gas silicate blocks has been created on the basis of the Minsk Silicate Products Plant, a branch of JSC Belarusian Cement Plant, with the support of the scientific and technical Department of the Management Company of the BCC Holding. The customers were Chinese contractors leading the construction of an international standard football stadium and swimming pool in Minsk. In about a month, the path from the formulation of the task to obtaining a certificate was completed. Natalia Bedik, Deputy Head of NTU for Scientific Work and Long-term Development, told what difficulties they had to face and how they were overcome.

– The block density was required at the level of 700 kg per cubic meter, whereas the German Masa-Henke lines installed at the holding plants were originally designed for a material density of no more than 500-600 kg per cubic meter. But we considered it a matter of honor for ourselves and decided to try it. The main requirement of the Chinese contractors concerned the strength of the block: it had to be at least twice as much as that of standard products that are currently used on construction sites – 5 MPa. You need to understand: in order to get a certificate for a new type of product, it was necessary to lay some kind of safety margin over, that is, in fact, at the output we had to get a material with a strength of 6-7 MPa. When the block was submitted for certification, its strength exceeded 5 MPa, now it has already reached 7 MPa (cellular concrete tends to come to a state of equilibrium humidity over time; the drier it becomes, the higher its strength).

We have applied a technology that has not yet been used in mass production in Belarus. It was an absolute innovation for the Minsk SPP: the plant tried for the first time to mold the block using gypsum. Moreover, it was not natural, well-known, lump gypsum that was used (by that time there were logistical problems with the supply of gypsum from abroad), but synthetic, which is produced from production waste at JSC SvetlogorskKhimvolokno. The difficulty was that synthetic gypsum is a loose, highly dispersed powder that is difficult to dose, inject, etc. The fact that the task was solved is a great merit of the MSSP leadership, its key specialists and personally Director Denis Yarmak.

Experiments continue: the goal is to further increase the strength of the block, while trying to reduce its density as much as possible. In particular, the specialists tried the dispersed reinforcement of gas silicate blocks with various mineral fibers. First of all, asbestos as the most affordable and cheap natural raw materials. Ground basalt fiber has also been tested in this capacity, which, as a result of negotiations, was developed for the needs of the BCC and kindly presented to it by JSC Polotsk-Fiberglass. Similar experiments have not been conducted in the country yet.

The scope of further application of the «superblock» has yet to be determined. It is quite possible, for example, that this is a good solution for non-standard objects, projects that do not involve additional reinforcement with reinforced concrete columns, etc., to create open spaces.